The technology of production of feed meal from fish waste is performed in a special installation IDS-50.

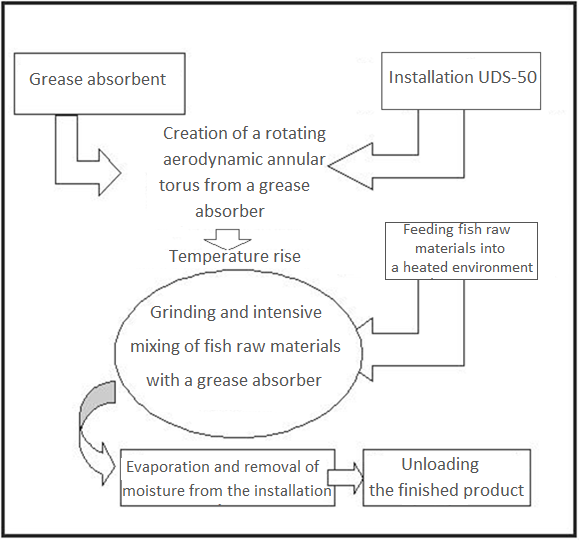

For the preparation of BKR in the metal thermos installation IDS-50 load dry loose filler - fat absorber (wheat bran, separated from the fiber sunflower meal). Filler - fat absorber, with the help of special knives that rotate at a speed of 2000 revolutions per minute, in a few seconds turns into a dusty pillar. The blades bring to dust the air content of the metal thermos.

Turbulent air captures the particles of the filler - the fat absorber from the bottom of the thermos, gives them acceleration in the mode of centrifugal circular motion and raises them in a spiral at the expense of special guide bumpers mounted on the inner surface of the thermos. As a result of friction, the aerodynamic mixture is heated. Within a few seconds of the rotor, the dry filler particles form an aerodynamic annular torus, constantly stirring over the entire height of the thermos. Next, the bottom of the thermos feeds fish raw in a ratio of 1:7 with filler. The knives of the device grind this raw material to a particle size of 0.1-0.8 mm, give it acceleration, and send it into the ring torus, where it is mixed with the filler for several minutes.

During this time, controlled internal friction processes raise the temperature of the mixture to 105-125 ° C. Thanks to this, the hygroscopic moisture of the mixture is converted to steam and removed. Fish proteins and fats are successfully sorted on the media surface. With a humidity of 7-9 units, the finished product BKR is sent from the thermos of the apparatus for cooling and sifting, packed in appropriately labeled packaging.